5. Rotor construction

The magnet rotor is also a casting. There is also a procedure later for assembling

the parts. First collect together the magnet plates, magnet blocks, stainless wire

rope, etc. as described next.

Magnet plates

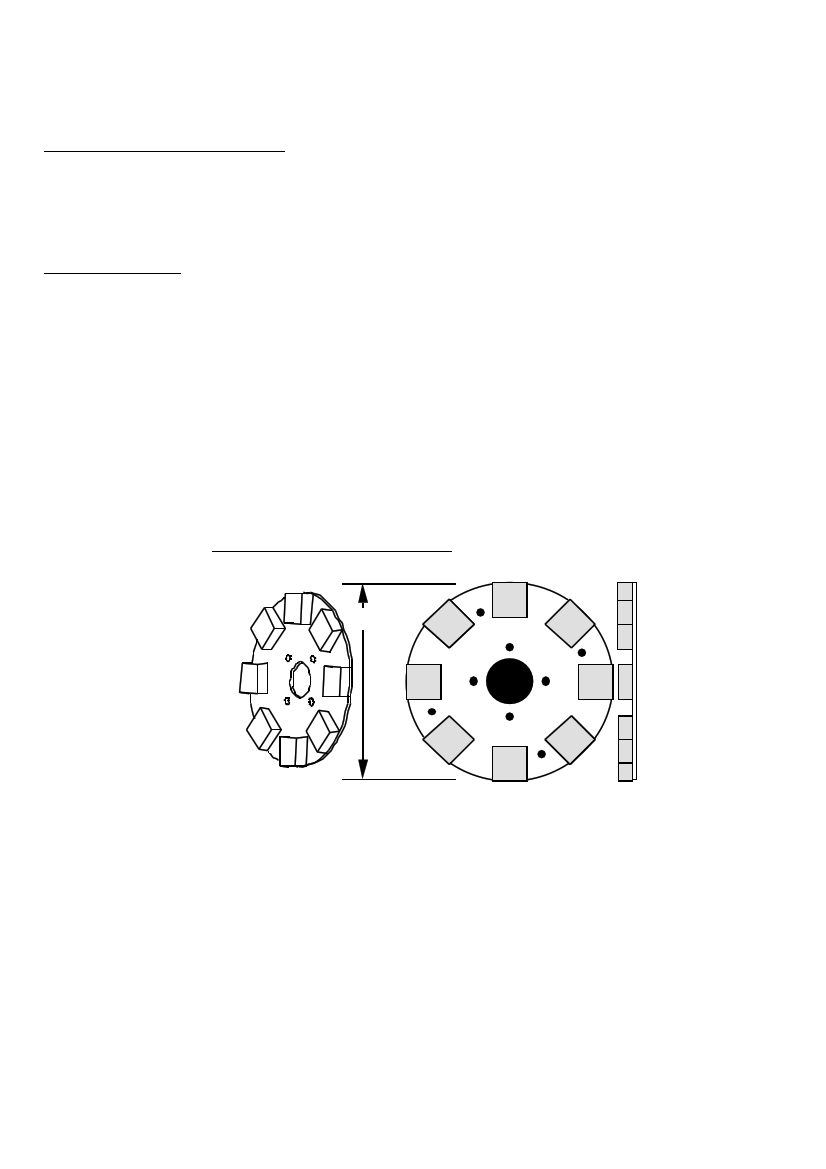

Each magnet rotor is built on a steel disk, 6mm thick. See diagram 32. Do not use

aluminium or stainless steel for this disk! The disks have to be made of magnetic

material. The disk has holes to mount it to the hub - in this manual the hub has four

holes, each 10mm diameter, on a circle at 4 inches (102mm) PCD. If a different hub

is chosen, then all the jigs and moulds must match this hub.

At the centre of the disk is a 65mm diameter hole. There should also be four holes

drilled and tapped (threaded) for M10 rod between the magnet positions, at 220mm

PCD. Screw four pieces of M10 rod, 20mm long, into these holes. These will bond to

the resin and help to secure the casting onto the disk.

32. MAGNET ROTOR DISK

305mm

The magnet plates must be flat, not warped. It is not easy to cut the outer circle

without warping the plate. A guillotine can cut steel plate into an octagon (see

diagram 33), without warping the plate. This is an alternative way to make the

rotor disk. First cut a square, draw a circle on it, and then cut off the corners at 45

degrees. The length of each edge is 116 mm.

The magnets will be placed on the corners of the octagon.

PMG manual

page 31

June 2001